The artificial rice production line equipment is a specialized equipment used for making artificial rice, and its working principle mainly includes the following steps:

1. Raw material selection: Select high-quality grains, beans, etc. as raw materials, and undergo pre-treatment processes such as cleaning and soaking to ensure the quality and hygiene of the raw materials;

2. Grinding process: The pre processed raw materials are fed into a grinder for crushing, separation, and grinding to obtain delicate powdered raw materials;

3. Forming process: The ground raw materials are added with appropriate water and mixed, and then molded into artificial rice particles through a mold;

4. Drying process: The formed artificial rice is fed into a dryer for drying treatment to achieve appropriate moisture content and texture;

5. Packaging process: After testing and screening, the dried artificial rice is packaged for transportation and sales.

The artificial rice production line equipment has brought new development opportunities to the grain processing industry through its efficient, stable production capacity and customizable characteristics. It not only meets the diverse and nutritious food needs of consumers, but also promotes the upgrading and transformation of the food industry. With the rapid development of technology and the continuous growth of market demand, this production line is expected to achieve more widespread application and promotion in the future.

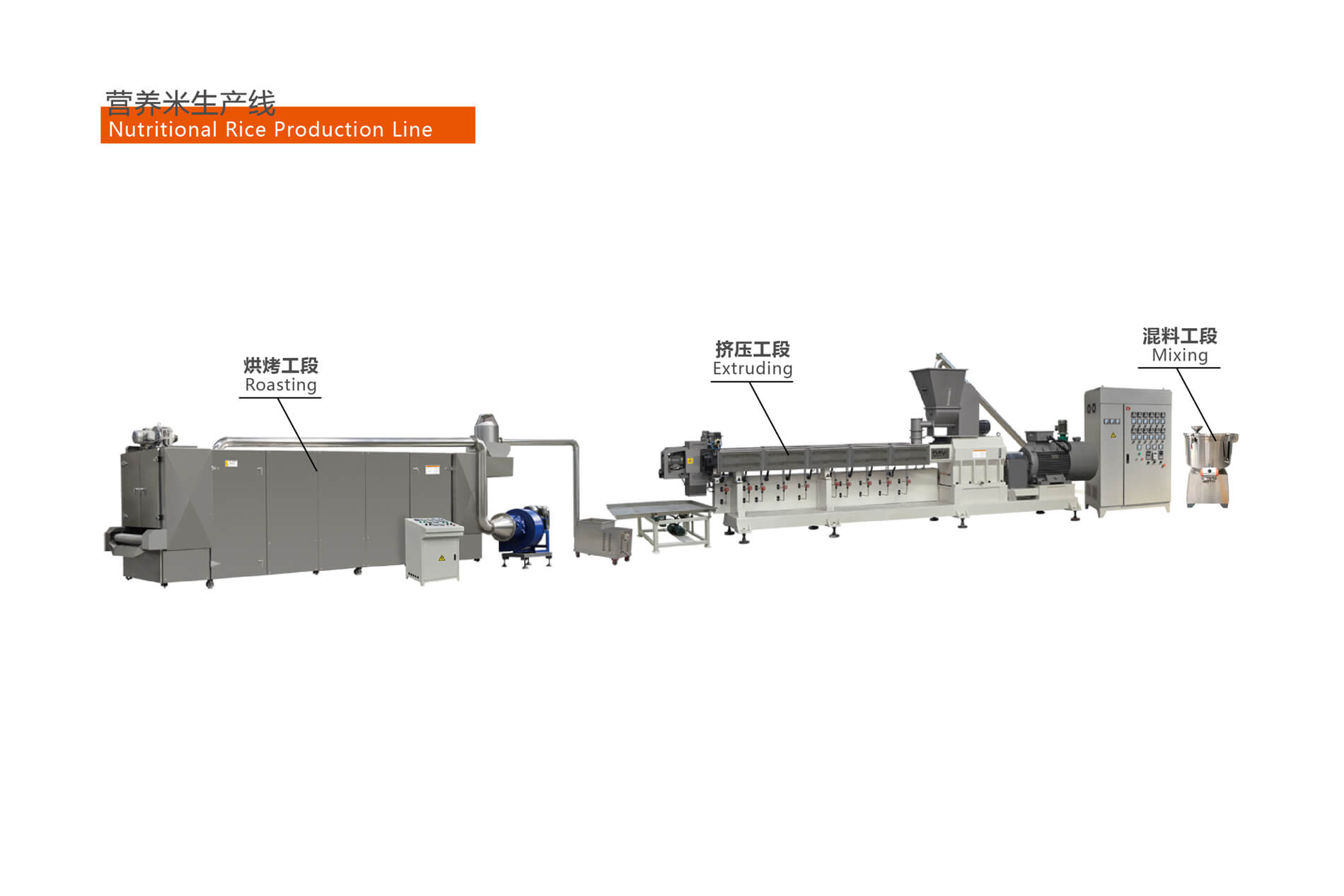

The artificial rice production line and artificial rice endows rice with unique shape, taste, and color, and adapts to the constantly developing market of health and wellness foods with scientific nutritional ratios and easy digestion. Reasonable structural design, special materials, and fast self-cleaning performance ensure the stability of the machinery and facilitate maintenance. Easy to operate, precise parameter control ensures that the product is completed within specific temperature, pressure, humidity, and time. The nutritious rice production line is composed of a mixing machine, a twin-screw extruder, an air blower, and a three-layer oven, catering to the diverse shapes and flavors of various groups of people.