The soy protein meat production line is a “plant meat” produced by a twin-screw puffing machine, using soybeans with a protein content of 70% to produce various types of meat according to the formula. The products produced by this production line have strong meat texture, good fiber status, and high toughness, and are highly favored by manufacturers. The product can be added to ham, sausages, canned foods, and various ready to eat products to enhance the chewiness of the food.

Twin screw puffing machine is a type of soy protein meat production line equipment that uses twin screws for material extrusion and puffing, combined with our company’s rich experience in the research and development of puffing food machinery over the years, to produce puffing food equipment suitable for China’s national conditions. The characteristics of this equipment are: according to market demand, it can use corn, rice, millet, black rice, mung beans, buckwheat, oats and other non ancient miscellaneous grains as raw materials, and through forced extrusion, puffing, shaping and drying, oil spraying, seasoning, and corresponding auxiliary processes, to process puffed food with various flavors, sandwich food, nutritional food, puffed snack food, and pet food. The soy is designed reasonably, has a high degree of automation, high output, and good technology. The main machines are all controlled by frequency converters for speed regulation, which is powerful and powerful.

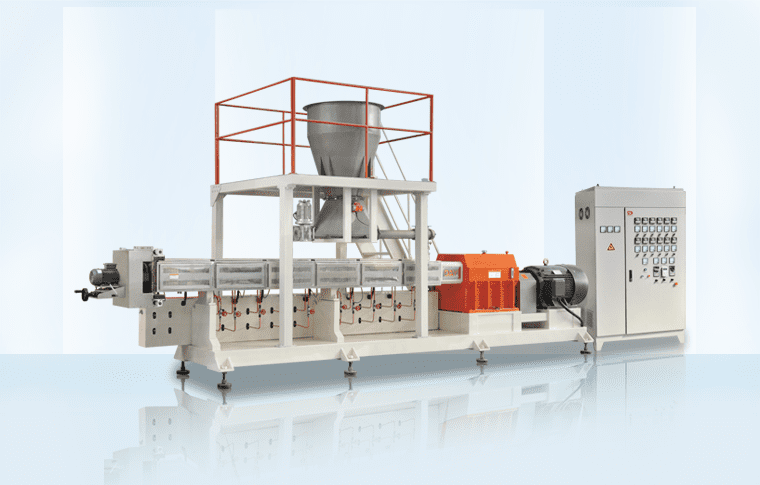

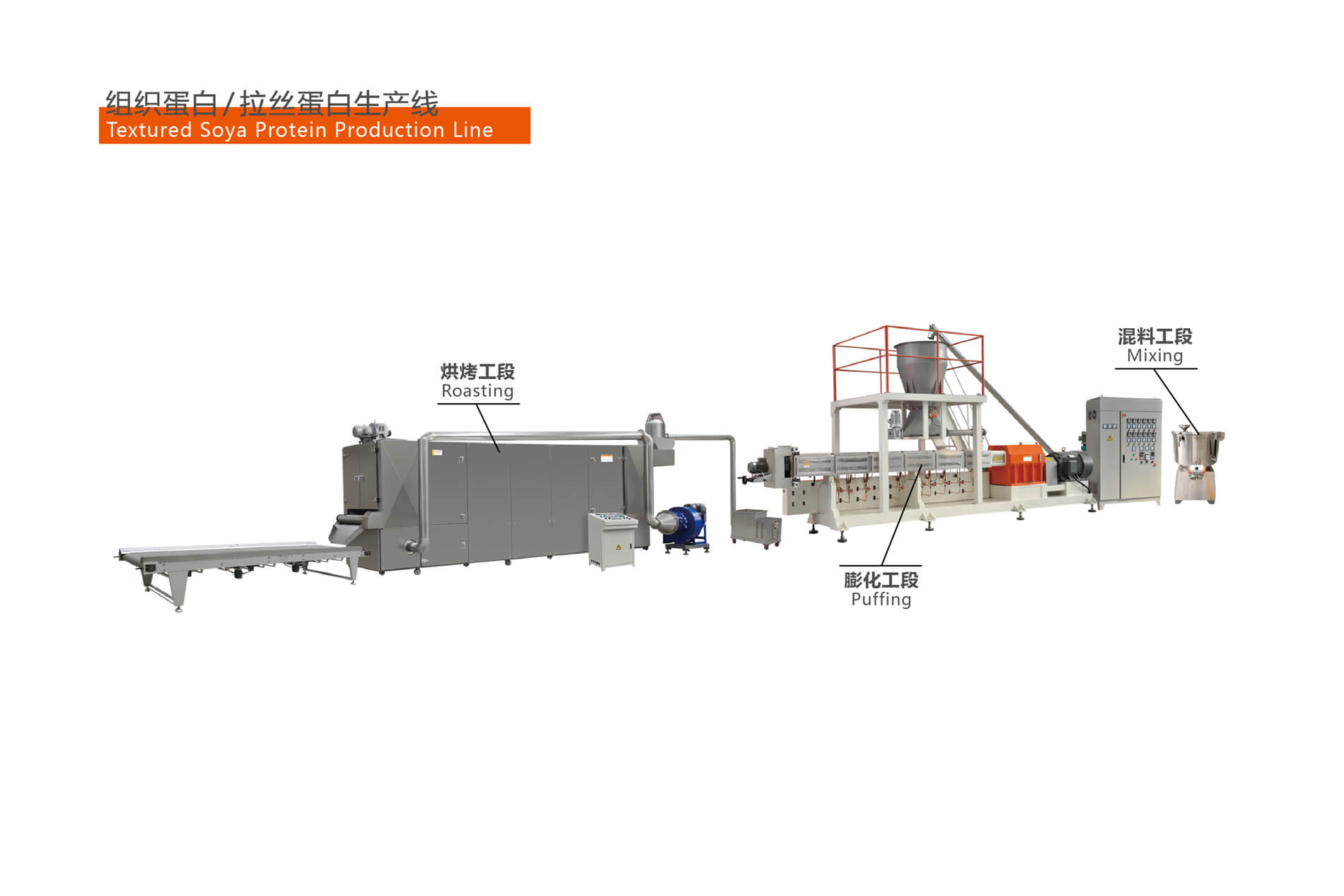

The tissue protein meat production line includes equipment such as a mixing machine, a spiral material extractor, a screw extrusion puffing machine, an air blower, an oven, and a cooling conveyor. Among them, the MT twin screw extrusion puffing machine – food machinery equipment network can complete a series of process processes such as material mixing and homogenization, kneading and shearing, steaming and cooking, high-temperature sterilization, and extrusion molding. This production line makes it possible to produce high-strength, high toughness tissue proteins, brushed proteins, and other meat products.

Adopting advanced frequency conversion speed regulation technology, the power is stronger, the operation is smoother, and the power is saved more. There is a forced lubrication system to ensure a longer service life of the transmission part, with visual automatic temperature control system, self-cleaning function, etc. When puffing products, the twin-screw machine is more stable. It consists of a feeding system, an extrusion system, a rotary cutting system, a heating system, a transmission system, and a control system. The main motor is a special motor with a strength rating of F grade. The passport is detachable and uses a baffle to effectively separate the belt and materials, preventing materials from sticking to the belt. The screw has a self-cleaning function, and there is no need to disassemble the screw for cleaning during shutdown.