The cheetos kurkure niknaks production line is an automatic equipment specially used to manufacture millet bars. The millet bar is a popular puffed snack, usually made of corn flour or other grain powders. The following are the main characteristics and advantages of the corn noodle production line:

Features:

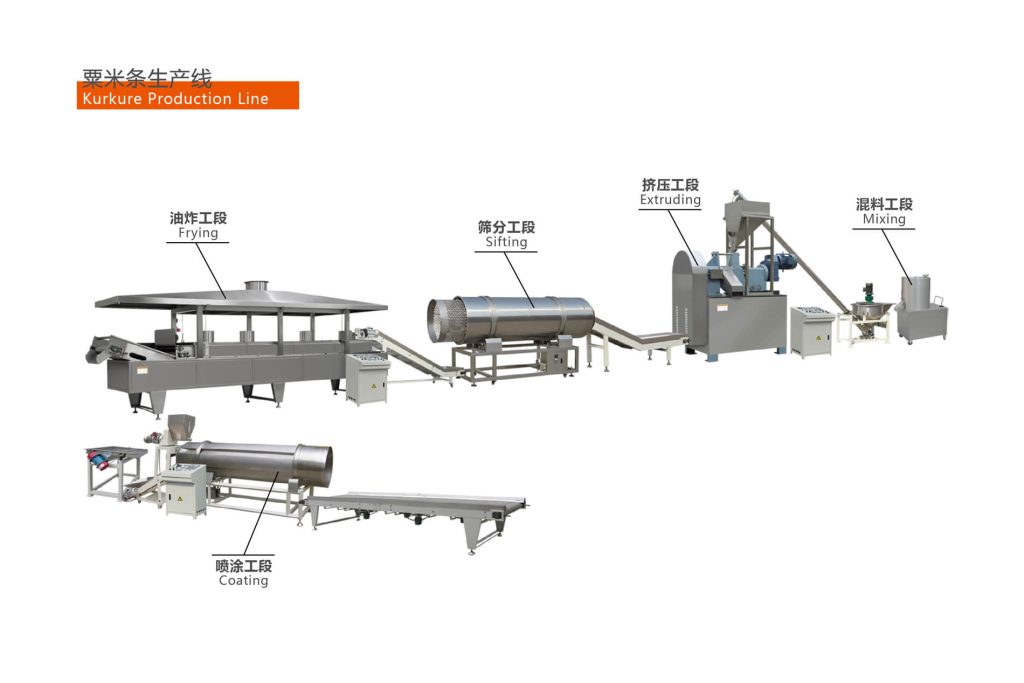

Automated production: The cheetos kurkure niknaks production line adopts highly automated processes, which can automatically complete various production processes such as raw material supply, mixing, extrusion, puffing, cutting, cooling, and packaging, reducing manual intervention and improving production efficiency.

Versatility: These cheetos kurkure niknaks production line typically have multiple functional modules that can produce corn noodle products with different flavors, colors, and shapes to meet the needs of different markets and consumers.

Accurate formula control: The cheetos kurkure niknaks production line can accurately control the proportion and formula of raw materials, ensuring that the ingredients of each product meet quality standards.

High efficiency: The cheetos kurkure niknaks production line is usually able to produce a large number of corn noodle products with high efficiency, suitable for mass production.

Food Safety and Hygiene: These production lines are typically made of food grade stainless steel or other easy to clean materials, which helps maintain food safety and hygiene standards.

Packaging and Printing: The cheetos kurkure niknaks production line typically includes printing machines integrated with packaging equipment to produce labels and packaging materials, ensuring that product identification and packaging comply with regulatory and brand requirements.

Traceability: Modern production lines usually have data monitoring and recording functions, which can track the production parameters and product quality of each batch for quality control and traceability.

Advantages:

Improving production efficiency: Automated cheetos kurkure niknaks production line can produce a large number of corn strips in a short period of time, reducing production cycles, and improving production capacity and efficiency.

Consistent product quality: Due to automation control, the cheetos kurkure niknaks production line can ensure that each product maintains consistent quality, avoiding the impact of human factors on product quality.

Reduce labor costs: Compared to manual production, the production line requires less labor, thereby reducing labor costs.

Customizability: The cheetos kurkure niknaks production line can usually be customized according to production needs to meet the production of different scales and types of corn strips.

Energy saving: Some corn noodle production lines adopt energy-saving technology, which reduces energy consumption and helps to reduce production costs.

Overall, the characteristics and advantages of the cheetos kurkure niknaks production line include automated production, versatility, precise control, high efficiency, food safety, packaging and printing, traceability, and cost reduction. These characteristics and advantages make it an important equipment in the field of corn noodle production, helping to improve production efficiency, ensure product quality, and meet the market demand for corn noodle products.